Bayonet Nut Connector Market Size, Share, Growth & Industry Analysis, By Product Type (Circular Bayonet Connectors, Rectangular Bayonet Connectors, Hybrid Connectors) By Material (Metal (Stainless Steel, Aluminum), Plastic, Composite) By Application (Aerospace & Defense, Automotive, Industrial Equipment, Medical Devices, Energy & Power) By End-User (OEMs, System Integrators, Maintenance & Repair Facilities), and Regional Analysis, 2024-2031

Bayonet Nut Connector Market: Global Share and Growth Trajectory

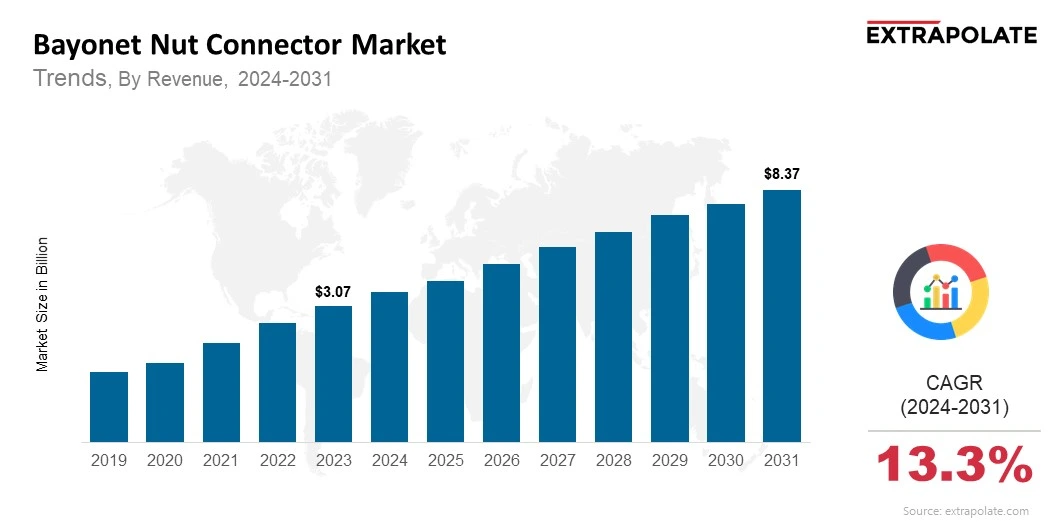

The global Bayonet Nut Connector Market size was valued at USD 3.07 billion in 2023 and is projected to grow from USD 3.50 billion in 2024 to USD 8.37 billion by 2031, exhibiting a CAGR of 13.3% during the forecast period.

The global Bayonet Nut Connector market is gaining remarkable traction as industries seek secure, quick-connect solutions for electrical and electronic applications. Designed with a distinctive quarter-turn locking mechanism, bayonet nut connectors offer superior reliability, vibration resistance, and ease of use in challenging environments. From aerospace to automotive and industrial automation, these connectors are becoming the preferred choice for robust and efficient power and signal transmission.

This upward trajectory is fueled by increased demand for compact, high-performance interconnect solutions across sectors. As the trend toward miniaturization and higher electrical density continues, bayonet-style connectors are evolving to support high-voltage, high-speed data transfer, and complex circuitry. Innovations in materials, contact plating, and sealing techniques are driving improvements in connector durability, environmental resistance, and electromagnetic compatibility (EMC). As global industries push for smarter, safer, and faster connections, the Bayonet Nut Connector market is positioned for sustained growth over the forecast period.

Key Market Trends Driving Product Adoption

Key Market Trends Driving Product Adoption

Several notable trends are accelerating the adoption of bayonet nut connectors across diverse sectors:

Surge in Aerospace and Defense Applications

The aerospace and defense industries have long demanded robust connectivity solutions capable of withstanding extreme conditions. Bayonet nut connectors, known for their secure locking and resistance to shock and vibration, have become essential in mission-critical systems such as avionics, radar systems, and ground control equipment. As governments worldwide increase defense spending and upgrade aerospace infrastructure, the demand for advanced interconnect solutions continues to grow.

Growth of Industrial Automation

As Industry 4.0 drives the adoption of smart manufacturing and automation technologies, bayonet nut connectors play a pivotal role in machine-to-machine communication. Their ease of installation, low maintenance requirements, and resilience in industrial environments make them ideal for robotic arms, control panels, and programmable logic controllers (PLCs). The need for reliable and modular connectivity solutions is directly boosting product penetration in factory automation.

Expansion of Electric and Hybrid Vehicles

Electric vehicles (EVs) require compact, vibration-resistant connectors that can support high-voltage power systems and communication interfaces. Bayonet nut connectors fulfill these requirements by offering secure and repeatable connections in confined spaces. As EV adoption accelerates globally and automotive manufacturers invest in lightweight, modular architectures, bayonet connectors are being integrated into onboard charging systems, battery management systems, and infotainment devices.

Push for Environmental Resilience and Sealing

Connectors operating in harsh outdoor or marine environments require protection against water, dust, and corrosive elements. Bayonet nut connectors are increasingly equipped with IP-rated seals and corrosion-resistant materials such as stainless steel and thermoplastics. The growing need for ruggedized connectors in oil & gas, mining, and renewable energy sectors is enhancing product demand for harsh-environment applications.

Major Players and Their Competitive Positioning

The Bayonet Nut Connector market is characterized by strong competition among global and regional manufacturers focused on performance differentiation and product innovation. Key players include TE Connectivity Ltd., Amphenol Corporation, ITT Inc., Fischer Connectors SA, LEMO SA, Radiall SA, Smiths Interconnect, Souriau-Sunbank (Eaton), Glenair, and Bel Fuse Inc.

These companies compete by offering application-specific designs, customizing pin layouts, and innovating with new contact plating materials. Strategic collaborations, mergers, and product expansions are helping them capture market share across defense, industrial, and transportation sectors. Additionally, many are investing in digital configurators and smart assembly tools to streamline product selection and integration.

Consumer Behavior Analysis

Consumer preferences in the Bayonet Nut Connector market are shaped by the growing demand for reliable, modular, and field-serviceable connectors. The following behavior trends are significant:

Emphasis on System Reliability

End-users prioritize connectors that ensure stable signal transmission, especially in high-vibration and critical systems. The bayonet locking mechanism provides reassurance of secure mating, influencing adoption in mission-critical scenarios like aviation, medical equipment, and military operations.

Preference for Plug-and-Play Solutions

Bayonet connectors are valued for their quick-connect capabilities, allowing easy and error-free assembly without tools. This feature is particularly appreciated in field maintenance or temporary installation setups, making them popular among maintenance engineers and installation technicians.

Focus on Cost of Ownership

While the initial cost of bayonet connectors may be higher than simpler alternatives, buyers consider lifecycle costs, including reduced downtime, lower failure rates, and quicker maintenance. Many organizations are shifting from threaded or push-pull connectors to bayonet types due to their superior durability and long-term performance.

Demand for Customization

Consumers increasingly demand connectors tailored to specific use cases—whether for miniature medical devices or heavy-duty rail systems. Manufacturers offering modular design options, varied contact arrangements, and hybrid signal/power solutions gain favor among OEMs and system integrators.

Pricing Trends

Bayonet nut connectors pricing varies based on size, material, sealing level, contact density and certification (MIL-SPEC or IP ratings). Prices range from a few dollars for basic to several hundred dollars for aerospace grade.

Pricing is also influenced by volume, custom requirements and supply chain. As competition increases and economies of scale are achieved through mass production, prices are decreasing. Subscription based procurement and direct online sales are helping customers control costs.

Growth Factors

Several key drivers are driving the growth of the Bayonet Nut Connector market:

Infrastructure Modernization and Smart Cities

Global infrastructure projects are using intelligent systems for monitoring, communication and control. Bayonet nut connectors are becoming the go to choice for outdoor sensor networks, surveillance systems and public transportation due to their ruggedness and reliability in harsh environments.

Expanding Telecommunication Networks

5G and fiber optic rollouts require durable connectors for base stations, antenna arrays and data centers. Bayonet connectors provide EMI shielding and mechanical stability for high frequency applications. As bandwidth increases so does the need for secure and interference free connectivity.

Medical Electronics

Portable diagnostic devices, surgical instruments and patient monitoring systems require compact and user friendly connectors. Bayonet nut connectors are preferred for their ease of sterilization and secure fit. With healthcare innovation accelerating post COVID-19, demand for hygienic and reliable connectors is growing.

Electrification and Renewable Energy Growth

solar and wind power generation is increasing the demand for connectors that can withstand extreme environmental conditions. Bayonet connectors with their sealing capabilities and mechanical reliability are being used in power inverters, energy storage systems and control cabinets in these sectors.

Regulatory Landscape

Bayonet nut connectors are subject to stringent quality, safety, and environmental regulations, especially when used in mission-critical or hazardous applications:

- MIL-SPEC Certification: In aerospace and military applications, connectors must comply with MIL-DTL-26482, MIL-DTL-38999, and other military specifications to ensure interoperability, ruggedness, and reliability.

- IP and NEMA Ratings: In industrial and outdoor environments, connectors must meet ingress protection standards (e.g., IP67, IP68) and NEMA ratings to ensure resistance to dust, water, and corrosion.

- RoHS and REACH Compliance: To meet global environmental safety norms, connectors must be free of hazardous substances and fully traceable under REACH and RoHS directives.

- ISO 9001 and AS9100: These standards govern quality assurance in manufacturing processes, ensuring repeatability, traceability, and defect-free production, particularly for aerospace-grade connectors.

Recent Developments

Several advancements and business strategies have recently shaped the Bayonet Nut Connector market:

- Smart Connectors with Embedded Sensors: Leading players are integrating sensor modules into connectors to enable condition monitoring, fault detection, and predictive maintenance, particularly in high-value assets like aircraft and factory machinery.

- Miniaturization and High-Density Connectors: Innovations in contact arrangement and insulation technology have enabled the development of miniaturized bayonet connectors with high pin counts for use in medical devices and wearables.

- Mergers and Strategic Alliances: Notable acquisitions include TE Connectivity’s expansion in the military/aerospace sector and Amphenol’s strategic partnerships in the rail and energy sectors. These moves are consolidating market share and expanding technological capabilities.

- Digital Customization Platforms: Players are launching online configuration tools allowing users to design and order connectors based on specific technical parameters, expediting procurement and improving user satisfaction.

Current and Potential Growth Implications

Demand-Supply Analysis

Global demand for bayonet nut connectors is outpacing traditional connector formats in several sectors. Suppliers are ramping up capacity and expanding local manufacturing hubs to shorten lead times and reduce logistics costs. However, volatility in raw material prices and geopolitical tensions continue to impact supply chains.

Gap Analysis

While product innovation is robust in high-end segments, there remains a gap in affordable, standardized bayonet connectors for small and medium-sized enterprises. Manufacturers have an opportunity to target this underserved segment with cost-effective, mid-range offerings tailored to non-critical applications.

Top Companies in the Bayonet Nut Connector Market

- TE Connectivity Ltd.

- Amphenol Corporation

- ITT Inc.

- Fischer Connectors SA

- LEMO SA

- Smiths Interconnect

- Radiall SA

- Glenair

- Souriau-Sunbank (Eaton)

- Bel Fuse Inc.

Bayonet Nut Connector Market: Report Snapshot

Segmentation | Details |

By Product Type | Circular Bayonet Connectors, Rectangular Bayonet Connectors, Hybrid Connectors |

By Material | Metal (Stainless Steel, Aluminum), Plastic, Composite |

By Application | Aerospace & Defense, Automotive, Industrial Equipment, Medical Devices, Energy & Power |

By End-User | OEMs, System Integrators, Maintenance & Repair Facilities |

By Region | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

Bayonet Nut Connector Market: High-Growth Segments

- Aerospace & Defense: This segment is witnessing significant growth due to increasing defense budgets and aircraft production, especially in North America and Asia.

- Industrial Automation: As smart factories become more prevalent, demand for rugged, easily serviceable connectors continues to rise.

- Medical Devices: Bayonet connectors' precision, sterilizability, and compact form factor are driving adoption in surgical and diagnostic equipment.

Major Innovations

- EMI-Shielded Connectors: Shielding materials and conductive coatings are being improved to minimize electromagnetic interference in high-frequency environments.

- Modular Hybrid Designs: Connectors now support both power and signal contacts in a single housing, improving space efficiency and installation ease.

- 360° Locking Mechanism Enhancements: New variants offer tactile feedback and visual confirmation of full engagement, improving installation confidence.

Bayonet Nut Connector Market: Potential Growth Opportunities

- Adoption in Emerging Economies: Industrial and infrastructure projects in Southeast Asia, Africa and Latin America are opening up new opportunities for bayonet connector adoption.

- Integration with IoT and Industry 4.0: As machines and devices get connected, smart connectors with self-diagnostic capabilities will see more demand.

- Expansion into E-Mobility and Autonomous Systems: As EV platforms and autonomous vehicle systems get more advanced, compact and durable interconnects will be more critical.

Extrapolate Research says:

The Bayonet Nut Connector Market is growing fast, driven by the need for secure high performance interconnects in key industries. With applications in aerospace, automotive, medical and industrial automation, these connectors are winning over traditional options. As manufacturers innovate in miniaturization, environmental protection and smart integration, bayonet connectors are becoming the go to connectors for modern electrical systems. With their proven reliability and flexibility, these connectors will continue to evolve and take a bigger share of the global connector market.

ARE YOU SEEKING COMPREHENSIVE INSIGHT ON VARIOUS

MARKETS?

CONTACT OUR EXPERTS TODAY

Bayonet Nut Connector Market Size

- June-2025

- 148

- Global

- semiconductor-electronics

Related Research

1,5-pentanediamine (Cadaverine)-Global Market Status & Trend Report 2022-2030 Top 20 Countries Data

December-2020

26650 Cylindrical Lithium Ion Battery Market Insights 2022, Global Analysis and Forecast to 2030

May-2021

2K Panel-Global Market Status and Trend Report 2015-2026

November-2020

300mm Wafer Carrier Boxes-Global Market Status & Trend Report 2022-2030 Top 20 Countries Data

January-2021

3D IC & 2.5D IC Packaging-Global Market Status & Trend Report 2022-2030 Top 20 Countries Data

November-2020