Industrial Tube Filling Machines Market Size, Share, Growth & Industry Analysis, By Product Type (Horizontal Tube Filling Machines, Vertical Tube Filling Machines), By Application (Pharmaceuticals, Cosmetics, Food & Beverages, Household, Others), By End User (Consumer Goods Manufacturers, Pharmaceutical Companies, Cosmetics Producers, Food Processors), and Regional Analysis, 2024-2031

Industrial Tube Filling Machines Market: Global Share and Growth Trajectory

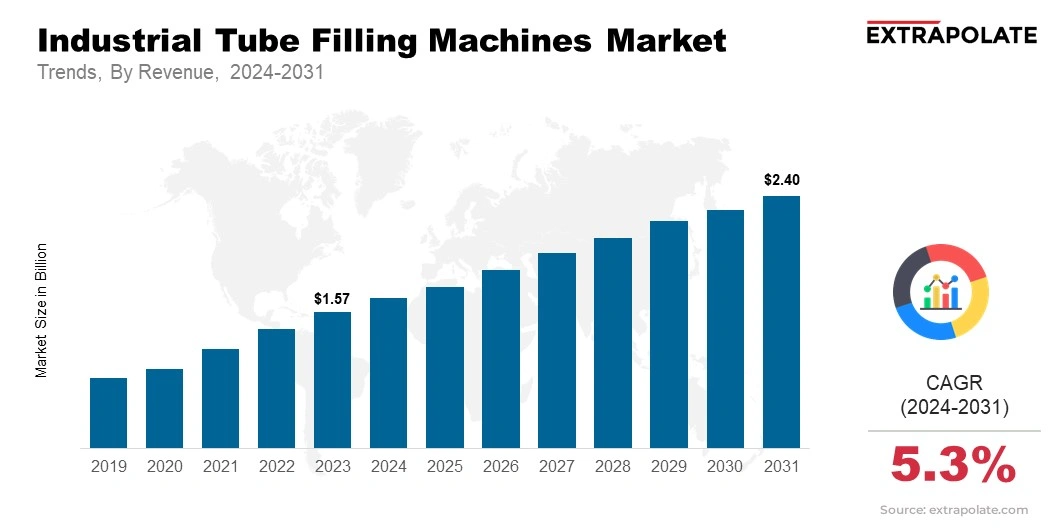

The global Industrial Tube Filling Machines Market size was valued at USD 1.57 billion in 2023 and is projected to grow from USD 1.67 billion in 2024 to USD 2.40 billion by 2031, exhibiting a CAGR of 5.3% during the forecast period.

The global market is witnessing steady growth, driven by the increasing demand for efficient packaging solutions in industries such as cosmetics, pharmaceuticals, food and beverages, and chemicals.

These machines are essential for automating the process of filling, sealing, and labeling tubes with a wide range of products, including creams, pastes, gels, and ointments.

As industries strive to enhance operational efficiency, reduce labor costs, and improve product quality, the adoption of advanced tube filling machines is becoming more prevalent across the globe.

The market is being driven by advancements in technology, which are enabling the production of more precise and versatile tube filling machines. Features such as automated filling, precise dosing systems, and the integration of sensors for quality control are improving the overall performance of these machines, making them more attractive to manufacturers.

The growing emphasis on hygiene, safety, and sustainability in packaging is also influencing the market, with manufacturers increasingly focusing on machines that can handle eco-friendly packaging materials, such as recyclable and biodegradable tubes.

In sectors such as pharmaceuticals and cosmetics, where product integrity and packaging accuracy are critical, industrial tube filling machines are gaining significant traction.

These machines ensure consistent filling, minimize waste, and maintain the sterility of products, which is particularly important in the pharmaceutical industry.

The ability to handle a variety of tube materials, including aluminum, plastic, and laminate, is further boosting the versatility and appeal of tube filling machines in different industries.

The rise of consumer demand for customized packaging and the growing trend toward small batch production are also fueling the adoption of industrial tube filling machines.

With the ability to handle multiple tube sizes and materials, manufacturers are able to offer a wide range of packaging options, from small-sized tubes for luxury products to larger tubes for everyday consumer goods.

As industries continue to prioritize efficiency, automation, and sustainability, the market is poised for long-term growth. Key players in the market are focusing on innovation, integrating cutting-edge technologies such as artificial intelligence and Internet of Things (IoT) to enhance the capabilities of tube filling machines.

The increasing demand for automation, coupled with the need for high-quality and cost-effective packaging solutions, is expected to drive significant growth in the market in the coming years.

Key Market Trends Driving Product Adoption

The industrial tube filling machines market is characterized by rapid advancements in automation and technology. Key trends driving market growth include:

- Automation and Precision: The increasing adoption of automated systems for tube filling processes is enhancing production efficiency, minimizing human error, and ensuring product consistency.

- Sustainability in Packaging: The rising focus on eco-friendly packaging materials and processes is encouraging the use of recyclable tubes and energy-efficient machines in industrial packaging lines.

- Customization and Versatility: The demand for machines that can handle a wide range of tube sizes and materials, as well as the flexibility to accommodate various filling products, is fueling innovation in the market.

- Advancements in Technology: Integration of smart technologies, such as IoT-enabled devices for real-time monitoring and predictive maintenance, is enhancing the overall performance of industrial tube filling machines.

- Hygienic and Sterile Operations: The growing need for hygienic and sterile environments, particularly in the pharmaceutical and cosmetic industries, is driving the demand for tube filling machines that comply with strict quality and safety standards.

Major Players and their Competitive Positioning

The industrial tube filling machines market is highly competitive, with several key players leading the market, including Bosch Packaging Technology, Norden Machinery, Coesia Group, and others. These companies are continuously innovating their product offerings and enhancing the capabilities of their machines to stay ahead in the market. Additionally, smaller players are entering the market with specialized solutions for niche applications, further intensifying the competition.

Consumer Behavior Analysis

The adoption of industrial tube filling machines is largely driven by manufacturers seeking to enhance productivity, reduce operational costs, and meet rising consumer demand for high-quality, well-packaged products. Key factors influencing purchasing decisions include:

- Efficiency and Speed: Manufacturers prioritize machines that can fill and seal tubes at high speeds without compromising on product quality.

- Cost-Effectiveness: With the increasing need for cost control, companies are opting for machines that offer a balance between high initial investment and long-term operational savings.

- Quality and Safety: Compliance with international quality standards, such as GMP (Good Manufacturing Practices), is a critical consideration for industries, especially pharmaceuticals and cosmetics.

- Customization: The ability to tailor machines to specific product requirements, such as varying viscosities and packaging types, is a key driver of adoption.

Pricing Trends

Pricing in the industrial tube filling machines market is influenced by factors such as machine complexity, automation levels, and material compatibility. While high-end, fully automated machines tend to command premium prices, there is also a growing market for semi-automated and manual machines that offer more affordable solutions for smaller manufacturers or specialized applications.

Growth Factors

Several key factors are driving the growth of the industrial tube filling machines market:

- Rising Demand for Packaging Solutions: The increasing demand for packaging across industries, especially for consumer goods, pharmaceuticals, and personal care products, is pushing the demand for industrial tube filling machines.

- Technological Advancements: Innovations such as IoT integration, AI-based systems for predictive maintenance, and more energy-efficient models are propelling market growth.

- Focus on Automation: Manufacturers are seeking to optimize production lines by adopting automated filling machines that increase throughput while minimizing labor costs and errors.

- Rising Environmental Concerns: The push towards sustainability is encouraging the development of tube filling machines that accommodate eco-friendly packaging materials.

Regulatory Landscape

The regulatory landscape for industrial tube filling machines varies across regions, with particular emphasis on the pharmaceutical and food industries. Compliance with international quality standards, such as GMP, ISO certifications, and food safety regulations, is essential for ensuring product safety and maintaining consumer trust.

Recent Developments

The industrial tube filling machines market is continuously evolving, with numerous innovations and developments shaping its growth:

- Smart Machines: The integration of IoT for real-time monitoring, process optimization, and predictive maintenance is becoming a key trend.

- Faster and More Efficient Machines: Innovations in machine design are enabling faster filling speeds without sacrificing precision or product quality.

- Energy Efficiency: Increasing focus on energy-efficient machines, driven by both cost considerations and environmental concerns.

Current and Potential Growth Implications

Demand-Supply Analysis

The demand for industrial tube filling machines is increasing across sectors like pharmaceuticals, cosmetics, and food packaging. However, the supply chain may face challenges due to raw material shortages and production delays.

Gap Analysis

While industrial tube filling machines have evolved significantly, there remain some areas for improvement, such as:

- Machine Compatibility: The need for machines that can handle diverse product formulations and tube materials remains a challenge.

- Cost-Effectiveness: Affordable solutions are required to cater to smaller businesses or those with limited budgets.

- Integration with Automation: Expanding the integration of AI and IoT for predictive maintenance and smart diagnostics can further enhance machine performance and reliability.

Top Companies in the Industrial Tube Filling Machines Market

- Bosch Packaging Technology

- Norden Machinery

- Coesia Group

- Marchesini Group

- IMA Group

- ACG Worldwide

- Optima Packaging Group

- Romaco Group

Industrial Tube Filling Machines Market: Report Snapshot

Segmentation | Details |

By Product Type | Horizontal Tube Filling Machines, Vertical Tube Filling Machines |

By Application | Pharmaceuticals, Cosmetics, Food & Beverages, Household, Others |

By End User | Consumer Goods Manufacturers, Pharmaceutical Companies, Cosmetics Producers, Food Processors |

By Region | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

High-Growth Segments

The following segments are expected to experience notable growth:

- Pharmaceutical Packaging: A growing demand for precise and hygienic filling processes for medicines and ointments.

- Cosmetics & Personal Care: Increasing demand for automated solutions to fill and seal cosmetic products in tubes.

Major Innovations

The industrial tube filling machines market is driven by constant innovation, such as:

- Advanced Automation: The introduction of machines with integrated robots for seamless filling and capping processes.

- Flexible Filling Solutions: Machines that can handle various viscosities and tube sizes to suit diverse products.

- Real-Time Monitoring: IoT-enabled machines offering real-time performance tracking, predictive maintenance, and data analytics.

Potential Growth Opportunities

Companies in the industrial tube filling machines market face the following challenges and opportunities:

- Intense Competition: The market is highly competitive, requiring constant innovation and differentiation.

- Technology Integration: Leveraging the latest technologies such as AI and IoT can provide growth opportunities.

- Demand for Customization: The need for machines that can handle diverse products and packaging types presents growth opportunities for specialized machine manufacturers.

- Environmental Regulations: Companies focusing on sustainable practices and energy-efficient machines are well-positioned for future growth.

Extrapolate Research says:

The global industrial tube filling machines market is set for significant growth, driven by innovations in automation, packaging sustainability, and industry-specific demands. Companies that focus on addressing challenges such as customization, cost-effectiveness, and advanced technological integration will be well-positioned to lead in this competitive market.

ARE YOU SEEKING COMPREHENSIVE INSIGHT ON VARIOUS

MARKETS?

CONTACT OUR EXPERTS TODAY

Industrial Tube Filling Machines Market Size

- April-2025

- 148

- Global

- machinery-equipment

Related Research

0-Global Market Status and Trend Report 2015-2026

November-2020

2 Side Seal Machines-Global Market Status & Trend Report 2022-2030 Top 20 Countries Data

December-2020

3 Side Seal Machines-Global Market Status & Trend Report 2022-2030 Top 20 Countries Data

December-2020