Ball Screw Market Size Share Growth & Industry Analysis, By Type (Rolled Ball Screws, Ground Ball Screws), By Application (Industrial Machinery, Robotics, Automotive, Aerospace, Medical Equipment, Others), By End-User (Automotive, Industrial, Aerospace, Robotics, Healthcare, Others), and Regional Analysis 2024-2031

Ball Screw Market: Global Share and Growth Trajectory

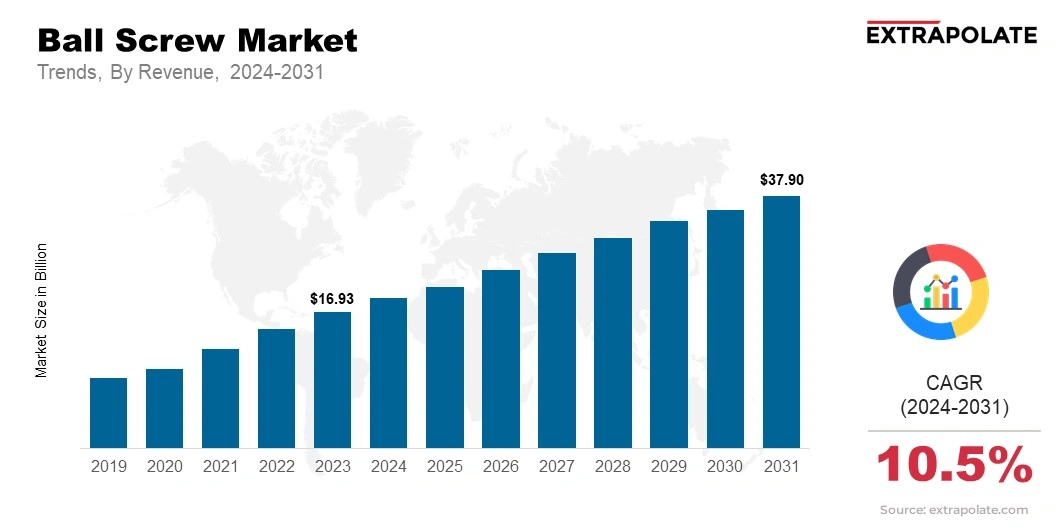

The global Ball Screw Market size was valued at USD 16.93 billion in 2023 and is projected to grow from USD 18.86 billion in 2024 to USD 37.90 billion by 2031, exhibiting a CAGR of 10.5% during the forecast period.

The global ball screw market is observing considerable progress, driven by developments in precision engineering intensifying focus on automation, and the rise in industrial applications across multiple industries like manufacturing, aerospace, automotive, and robotics.

Ball screws, recognized for their superior efficiency and minimal friction, are key elements in machines and equipment where precision movement is of utmost importance. They are instrumental in converting rotary motion into linear motion with limited consumption of energy, making them irreplaceable in industries that require unmatched precision and robustness.

Technological breakthroughs are propelling the market at lightning speed. Innovations in materials, design, and manufacturing techniques fuel this momentum. Meanwhile, automation is taking center stage, with robotics and CNC machinery leading the charge. This surge demands ball screws to provide manufacturers with automated precision.

The automotive industry, witnessing growth at a breakneck speed, is a key player in this ball screw boom. With electric vehicles (EVs) hitting the fast lane, the demand for ball screws is surging.

These sophisticated components are essential for steering systems, drive systems, and other precision applications. In the aerospace sector, their reliability is unmatched. Ball screws now play a key role in aircraft control systems and satellite positioning mechanisms, where accuracy is not just desired, but absolutely critical.

With the steady rise of the market, manufacturers are focused on enhancing the efficiency and longevity of ball screws, while simultaneously lowering maintenance expenses. The growth in the need for premium, long-lasting, and effective ball screws is contributing to the rising growth of advanced products that can resist severe conditions, like high loads, high speeds, and wide-ranging temperatures.

Geographically, North America, Europe, and Asia-Pacific are the dominant areas in the market. Asia-Pacific, specifically, is expected to undergo dynamic growth, propelled by industrialization, fast paced urbanization, and the increasing investments in the manufacturing sectors in countries such as China, Japan, and India.

In conclusion, the market all over the world is anticipated to see major growth as industries are progressing toward automation, precision manufacturing, and technological developments. The industry's momentum suggests continued success, with expanding changes coming up in several end-use sectors, strengthened by evolving advancements in ball screw technology.

Key Market Trends Driving Product Adoption

The ball screw market is influenced by the persisting technological innovations and dynamic industry needs. Multiple key trends are fuelling the incorporation of ball screws:

- Accuracy and Effectiveness: With the increasing demand for highly accurate motion systems, industries are progressively utilizing ball screws due to their efficiency of providing seamless and precise motion, particularly in applications that require precisely coordinated actions.

- Automation and the Growth of Robotics: The growth in the adoption of automation and robotics, specifically in the manufacturing, automotive, and aerospace sectors, is intensifying the need for ball screws. These components play a major role in guaranteeing the consistency and productivity of robotic arms, automated machinery, and CNC machines.

- Transition Towards Electric and Hybrid Vehicles: The automotive industry's shift toward electric and hybrid vehicles is propelling demand for ball screws in multiple applications, for example, power steering systems, throttle actuators, and seat adjusters.

- High Load and Speed Capabilities: Developments in ball screw designs are accelerating the progress of components that can withstand higher loads and rapid motion, increasing their use in high-requirement industries such as aerospace and heavy machinery.

Major Players and their Competitive Positioning

The ball screw market is competitive, with key players excelling in the innovation of products and gaining market share.

Prominent manufacturers like NSK Ltd., THK Co., Ltd., Bosch Rexroth AG, and SKF Group maintain dominance in the market with their wide-ranging product offerings, presence all over the world, and effort taken in research and development.

These companies focus on improving the effectiveness, accuracy, and lifetime of ball screws, in addition to discovering innovative applications in developing industries such as robotics, healthcare, and electric vehicles.

Consumer Behavior Analysis

Consumers in the market, mainly industrial manufacturers, are putting greater focus on the resilience, accuracy, and performance of ball screws. Factors that affect the behavior of consumers are:

- Precision and Quality: Manufacturers are giving more priority to ball screws that offer enhanced precision and durability, specifically for applications that need accurate and repeatable linear motion.

- Cost Efficiency: As competition intensifies in the ball screw industry, consumers are also worried about the affordability of the solutions that they are opting for, seeking premium products that offer extended durability at reasonable prices.

- Customization: The demand for customized ball screws which can be customized according to particular industrial needs is on the rise, specifically in industries such as aerospace, automotive, and robotics, where specialized features are essential.

- Technological Integration: Consumers are progressively looking for ball screws that incorporate well with advanced technologies like robotics, CNC machines, and automated production systems, enabling seamless workflows and increased efficiency.

Pricing Trends

The pricing of ball screws is dependent on factors like material, size, load capacity, and manufacturer. Premium ball screws with strengthened weight capacity, accuracy, and enhanced longevity typically come at a premium.

Nevertheless, the growing availability of cost-effective substitutes, along with the increasing demand for uniform components, is helping in reducing overall prices, making ball screws more easy to access for a diverse range of industries.

Growth Factors

Factors driving the growth of the market:

- Demand for Precision and Automation: The rising consumer interest in precise motion control systems in automated machinery, robotics, and automotive applications is one of the major contributors in the market.

- Technological Advancements: The sustained enhancements in ball screw technology, which include the advancement of energy-efficient designs tailored for high-capacity and fast-paced applications, are fuelling market growth.

- Increase in Manufacturing Activities: With the increasing focus on manufacturing excellence, especially in industries like aerospace, automotive, and industrial machinery, the demand for ball screws is poised for significant expansion.

- Rising Automotive and Electric Vehicle Production: The automotive industry, specifically with the move toward electric and hybrid vehicles, is driving the demand for ball screws in multiple applications, like power steering, adjustment seats, and throttle control systems.

Regulatory Landscape

The ball screw market is subject to strict regulatory requirements which relate to compliance requirements, safety, and impact on natural resources. Manufacturers must adhere to international standards like ISO 9001 for quality management systems and ISO 14001 for environmental management.

Governing authorities across various regions, such as the European Union and the United States, also enforce regulations for the safety and ecological impact of mechanical elements, which could impact the design and manufacturing of ball screws.

Recent Developments

Recent advancements in the market include:

- New Product Launches: Several manufacturers have introduced advanced- efficiency ball screws with superior load capacities, extended durability, and greater accuracy, meeting the growing needs of industries like aerospace and robotics.

- Partnerships and Collaborations: Companies in the market are creating strategic collaborations and partnerships to amplify their product range and improve their visibility in the market. These partnerships generally have their main focus on technological innovations and explore the newest applications in upcoming markets like electric vehicles and automation.

- Customization of Ball Screws: Manufacturers are expanding their range of custom-made ball screws that meet the exclusive parameters of numerous industries, guaranteeing enhanced versatility and increased customer contentment.

Current and Potential Growth Implications

- Demand-Supply Analysis: The demand for ball screws is anticipated to continue exceeding availability in rapidly expanding industries like robotics and electric vehicles. Regardless, the market is noticing a surge in production potential as companies are prioritizing investments in emerging technologies and production facilities to fulfil this demand.

- Gap Analysis: Even with the growth of the market, challenges persist in providing economical and reliable solutions for small-scale automation and mass production industries. Tackling these challenges will open up fresh prospects for manufacturers in the years to come.

Top Companies in the Ball Screw Market

- NSK Ltd.

- THK Co., Ltd.

- Bosch Rexroth AG

- SKF Group

- Koyo Seiko Co., Ltd.

- Hiwin Technologies Corp.

- NTN Corporation

- SCHNEEBERGER

- Jiangsu Xinhua Machinery Co., Ltd.

- CPC Motion Control, Inc.

Ball Screw Market: Report Snapshot

Segmentation | Details |

By Type | Rolled Ball Screws, Ground Ball Screws |

By Application | Industrial Machinery, Robotics, Automotive, Aerospace, Medical Equipment, Others |

By End-User | Automotive, Industrial, Aerospace, Robotics, Healthcare, Others |

By Region | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

High Growth Segments

The segments given below are most likely to experience a noticeable growth in the market:

- Robotics and Automation: With the fast-paced incorporation of robotics in manufacturing, logistics, and healthcare, the ask for ball screws in these applications is set to increase at a rapid rate.

- Automotive Applications: The transition to electric and hybrid vehicles is fueling the demand for ball screws in automotive applications, especially for power steering systems and other precision mechanisms.

Major Innovations

Innovations in the market include:

- High Load Capacity Designs: Manufacturers are creating ball screws that have the ability to handle greater loads and speeds, making them ideal for use in intensive applications like aerospace and heavy machinery.

- Energy-Efficient Models: Latest designs keeping their focus on minimizing consumption of energy and maximizing overall effectiveness are gaining traction, specifically in automation and industrial applications.

Potential Growth Opportunities

Opportunities for growth in the market include:

- Emerging Markets: Getting to know more about emerging economies in Asia-Pacific, Latin America, and the Middle East, where industrialization and manufacturing are making their mark at a fast pace, showcases a robust potential of growth for ball screw manufacturers.

- Smart Manufacturing and Industry 4.0: The incorporation of Industry 4.0 technologies and smart manufacturing solutions is set to fuel the demand for high-precision motion control systems, inclusive of ball screws.

Kings Research says:

The global ball screw market is rightly placed for constant development, propelled by advancements in technology, growth in automation, and the demand for systems with high accuracy making its mark across different industries. Manufacturers that keep innovation, efficiency, and customized products as their main aim will be strategically placed to fulfil the increasing demand for ball screws in the years ahead.

ARE YOU SEEKING COMPREHENSIVE INSIGHT ON VARIOUS

MARKETS?

CONTACT OUR EXPERTS TODAY

Ball Screw Market Size Share Growth

- February-2025

- 140

- Global

- machinery-equipment

Related Research

0-Global Market Status and Trend Report 2015-2026

November-2020

2 Side Seal Machines-Global Market Status & Trend Report 2022-2030 Top 20 Countries Data

December-2020

3 Side Seal Machines-Global Market Status & Trend Report 2022-2030 Top 20 Countries Data

December-2020