Manufacturing Execution System (MES) Market Size, Share, Growth & Industry Analysis, By Component (Software, Services) By Deployment (On-Premises, Cloud) By Industry (Automotive, Aerospace, Electronics, Pharmaceuticals, Food & Beverage, Chemicals, Others), and Regional Analysis, 2024-2031

Manufacturing Execution System (MES) Market: Global Share and Growth Trajectory

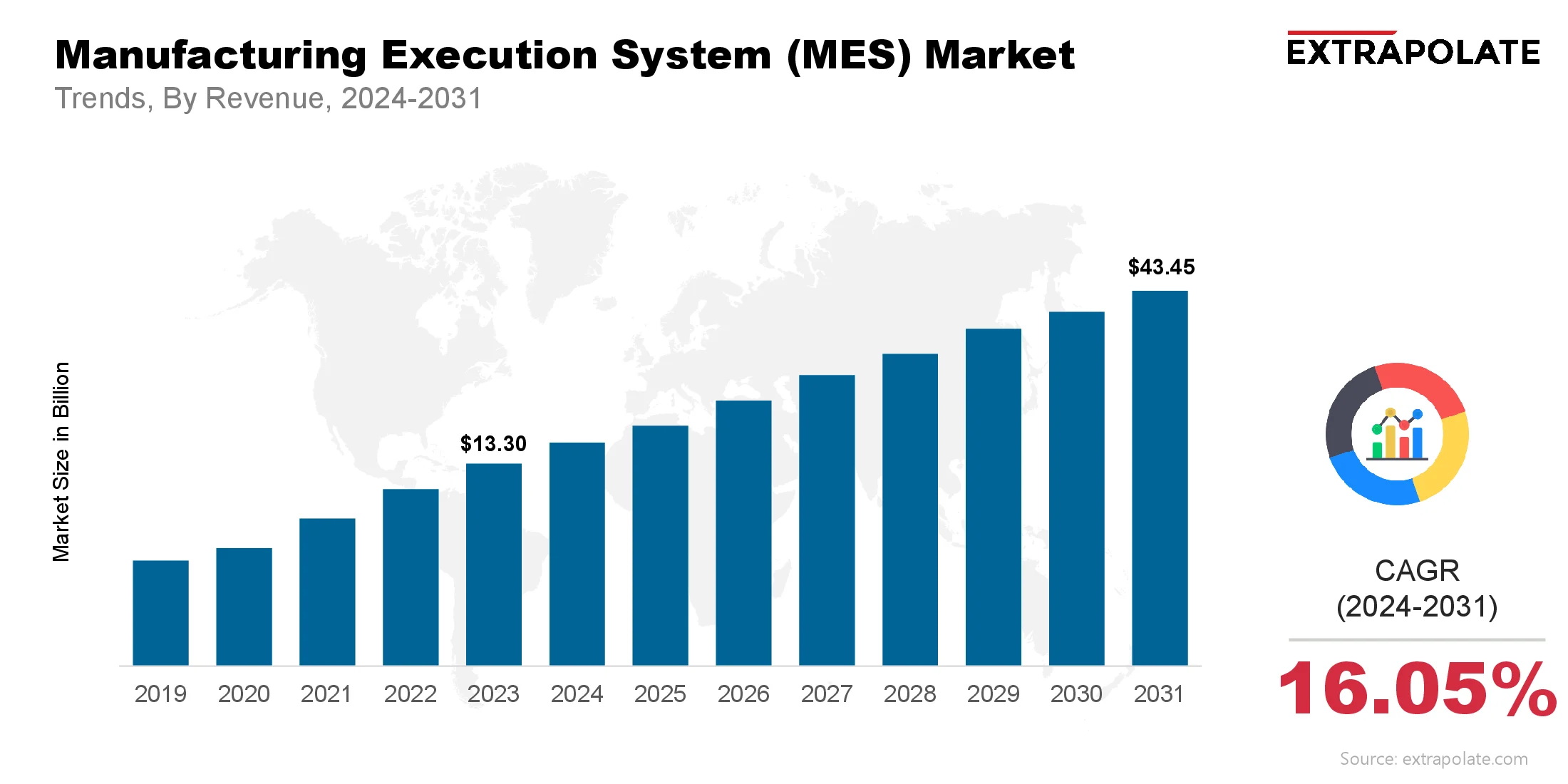

The global Manufacturing Execution System (MES) Market size was valued at USD 13.30 billion in 2023 and is projected to grow from USD 15.32 billion in 2024 to USD 43.45 billion by 2031, exhibiting a CAGR of 16.05% during the forecast period.

The global Manufacturing Execution System (MES) market is booming. Companies across industries are embracing digital transformation. As smart manufacturing and Industry 4.0 gain momentum, MES has become essential. It helps with real-time monitoring, management, and optimization of production.

MES acts as a bridge between enterprise-level planning systems and plant floor equipment. This connection streamlines workflows, improves product quality, and reduces operational inefficiencies. In recent years, the MES market has grown rapidly. Adoption is no longer limited to large multinational firms. Small and medium-sized enterprises (SMEs) are also investing in MES for scalable and cost-effective solutions.

Demand is especially high in industries like automotive, aerospace, pharmaceuticals, electronics, and food and beverage. These sectors need high levels of precision, traceability, and regulatory compliance. Technology is a key growth driver. Cloud-based platforms, IIoT integration, and AI and ML are making MES systems smarter and more agile.

These innovations give manufacturers deeper insights into operations. They can predict equipment failures and respond to market changes more quickly. North America and Europe hold major market shares. This is due to early adoption and strong industrial foundations. However, Asia-Pacific is becoming a key growth region. Rapid industrialization, government support for smart factories, and rising automation are fueling expansion in the region.

Key Market Trends Driving Product Adoption

Industry 4.0 and Smart Manufacturing

Industry 4.0 has put smart factories at the heart of industrial transformation. MES is the key to this by giving real-time visibility into every part of production. From machine health to quality compliance, MES is the foundation for intelligent decision making. Manufacturers now see MES as essential for smart workflows, predictive maintenance and seamless integration with cyber-physical systems.

Cloud Based MES Solutions on the Rise

Traditional MES systems required big upfront investment and infrastructure. But with cloud based solutions, MES is being democratised. Cloud MES offers scalability, reduced IT burden and collaboration across geographically dispersed production sites. The growing availability of software-as-a-service (SaaS) MES models is driving adoption among small and medium sized enterprises (SMEs) as well. In Nov 2024, Fusion Informatics launched its new Cloud Manufacturing Execution System (MES) a SaaS based platform for multi-site manufacturers to have real-time visualization, advanced analytics, scalability and ERP integration to streamline operations and optimize production across sites smartforge.

Compliance and Quality Assurance Requirements

With tightening regulations, especially in sectors like food & beverage, pharmaceuticals and aerospace, MES systems are becoming essential to ensure audit trails, batch traceability and documentation compliance. MES solutions allow real-time tracking and ensure that manufacturing processes meet internal standards and external regulations.

AI and IoT for Real-Time Optimisation

The integration of artificial intelligence (AI) and Internet of Things (IoT) into MES systems is making operations smarter. Real-time data from connected machines and sensors enables MES to forecast demand, detect anomalies and recommend process improvements. These smart features reduce waste, energy consumption and unplanned downtime. In April 2024, AVEVA announced a hybrid-cloud MES at Hannover Messe, where manufacturers can centralize and visualize production execution data from remote sites, using edge computing and AI/ML analytics for sustainability, efficiency and multi-site coordination.

Major Players and their Competitive Positioning

The MES market includes both long-established automation giants and newer software innovators. Competition is growing as vendors enhance their MES offerings to meet evolving manufacturing needs. Siemens AG, Rockwell Automation, Inc., Honeywell International Inc., Schneider Electric SE, Emerson Electric Co., ABB Ltd., Dassault Systèmes, General Electric Company, AVEVA Group plc, SAP SE.

Companies are investing in cloud-based MES platforms. They are also exploring digital twin technologies and AI-powered analytics. To stay competitive, many are forming strategic partnerships. Others are expanding through acquisitions. Frequent platform upgrades are also common. These efforts help them meet the changing needs of global manufacturers.

Consumer Behavior Analysis

- Operational Agility: Manufacturers are looking for agility to respond to supply chain disruptions, changing demand patterns and labor shortages. MES lets you change production plans in real-time, optimize resource usage and reduce cycle times so it’s a top priority.

- ROI and Cost Optimization: While MES deployment comes with upfront costs, businesses are increasingly seeing it as a long term investment with high ROI. Benefits like increased throughput, better inventory control, reduced rework and improved product quality justify the spend. This is driving adoption across industries.

- Modular and Scalable Solutions: Buyers today want MES platforms that are modular and can be customized to their specific operational needs. Scalability is another key factor as companies look for solutions that grow with their business without requiring a total infrastructure overhaul.

- Workforce Upskilling and Change Management: MES adoption also reflects growing comfort among workers with digital technologies. As industries invest in upskilling and digital literacy the workforce is getting more comfortable with advanced software systems and making MES integration smoother.

Pricing

MES implementation costs vary widely depending on system complexity, scale, deployment model (cloud vs on-premises) and industry specific features. On-premises MES solutions come with substantial upfront licensing and integration costs making them more suitable for large enterprises. Cloud MES solutions have subscription based pricing models which are more affordable and flexible.

Vendors are offering tiered pricing structures, bundling MES with support services, training and system upgrades. ROI based pricing and pay per use models are also gaining traction as companies look for cost effective ways to digitize.

Growth Factors

- Digital Transformation Speeds Up: Across industries digital transformation is accelerating and manufacturing processes need to be resilient and flexible. MES is at the heart of this, enabling automation, real-time monitoring and departmental collaboration.

- Multi-Site Operations and Global Supply Chains: Globalization and multi-site operations have created the need for centralized, standardized control systems. MES enables data to flow seamlessly across sites, aligns production strategies and synchronizes supply chains.

- Discrete and Process Industries Growing: Discrete manufacturing (e.g. automotive, aerospace, electronics) and process industries (e.g. chemicals, pharmaceuticals, F&B) are driving MES adoption. These industries require traceability, precision and compliance, all of which MES delivers.

- Investment in Smart Factories: Governments and private organizations are investing in smart factory initiatives. MES is at the centre of this, often part of public-private partnerships, industry consortia and funding programs to build digital manufacturing ecosystems.

Regulatory Landscape

MES needs to comply with various regulatory and industry standards to ensure data integrity, operational safety and quality compliance. Key regulatory considerations are:

- FDA 21 CFR Part 11 (for pharmaceuticals and life sciences): MES needs to provide electronic record-keeping and signature capabilities.

- ISO 9001 and ISO 13485 Standards: Focus on quality management systems and production traceability.

- GAMP 5 Guidelines: Software validation for automated systems in regulated industries.

- Good Manufacturing Practices (GMP): MES is key to GMP compliance across industries.

- Cybersecurity Frameworks: With digital connectivity MES needs to comply with NIST or IEC 62443 standards to protect manufacturing data.

These frameworks are shaping MES design and deployment, ensuring they meet industry-specific and jurisdictional requirements.

Recent Developments

AI-Driven Predictive Capabilities: New MES features include predictive analytics for equipment failure, scheduling and unplanned downtime.

- IoT and Edge: MES platforms are collecting machine level data through edge devices for real-time process optimization at the source.

- Unified Digital Platforms: Vendors are integrating MES with ERP, PLM and SCADA for end to end visibility and control across the value chain.

- Strategic Acquisitions: Siemens and Rockwell Automation have acquired MES startups to expand their portfolio.

- Vertical Specific MES Modules: Vendors are developing MES modules for pharmaceuticals, F&B and semiconductors to address their unique regulatory and operational needs.

These are the trends towards intelligent, interoperable and future proof MES.

Current and Future Impact

a. Demand Supply Analysis

As demand for MES increases especially in emerging markets, vendors are expanding product and service offerings. But shortage of skilled integrators and domain experts is limiting implementation capacity in some regions.

b. Gap Analysis

MES is adopted widely in large enterprises and regulated industries. But there is a big gap in SMEs due to cost and complexity. Vendors are responding with simple, modular MES and cloud deployments to bridge the gap and expand the market.

Top Companies in the Manufacturing Execution System (MES) Market

- Siemens AG

- Rockwell Automation, Inc.

- Schneider Electric SE

- Honeywell International Inc.

- Emerson Electric Co.

- ABB Ltd.

- Dassault Systèmes

- AVEVA Group plc

- SAP SE

- GE Digital

MES Market: Report Snapshot

Segmentation | Details |

By Component | Software, Services |

By Deployment | On-Premises, Cloud |

By Industry | Automotive, Aerospace, Electronics, Pharmaceuticals, Food & Beverage, Chemicals, Others |

By Region | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

MES Market: High Growth Segments

- Cloud MES: Cloud is expected to grow the fastest as it’s lower cost and more scalable.

- Pharmaceutical and Life Sciences: Regulatory compliance and traceability is driving high MES adoption in this industry.

- SMEs in Emerging Markets: Increasing digital literacy and access to cloud solutions is driving faster MES adoption in developing regions.

New Developments

- Digital Twin Integration: MES platforms are now integrating digital twin to simulate and optimize production virtually.

- AI-Driven Decision Support: Advanced MES systems are providing real-time suggestions to operators and supervisors.

- Mobile MES Apps: Mobile MES interfaces are enabling on-the-go monitoring and control of manufacturing operations.

MES Market: Growth Areas

- Emerging Market Expansion: Asia-Pacific and Latin America is ready for MES growth as industrial activity is growing and digital transformation is on the agenda.

- Sustainability and Green Manufacturing: MES is key to optimizing energy consumption and minimizing waste to support manufacturers’ sustainability goals.

- 5G and Edge AI: Future MES will leverage 5G for ultra-low latency and edge AI for decentralized decision making.

Extrapolate says:

The Manufacturing Execution System (MES) market is set for strong growth. Manufacturers are aligning with Industry 4.0 and looking for smarter ways to manage production. The focus is shifting to real-time visibility, automation, and data-driven control. This is pushing MES adoption across various industries.

As AI, IoT, and cloud technologies come together, MES platforms are evolving. They are becoming more flexible, scalable, and intelligent. Vendors offering modular and interoperable solutions have a clear edge. Compliance and integration capabilities are also key to gaining market share. MES is no longer just about tracking production. It now plays a central role in creating smart, agile, and resilient manufacturing systems. With rising demand and ongoing innovation, the global MES market is expected to grow significantly over the next decade.

ARE YOU SEEKING COMPREHENSIVE INSIGHT ON VARIOUS

MARKETS?

CONTACT OUR EXPERTS TODAY

Manufacturing Execution System

- July-2025

- 140

- Global

- information-technology-communication-iot

Related Research

2018-2023 Commercial Interior Design Market Size, Share & Trends Analysis Report By Application ( O

March-2021

2018-2023 Industrial Product Design Market Size, Share & Trends Analysis Report By Application ( Tr

March-2021

2D Animation Software Market Size, Share & Trends Analysis Report By Application (Construction Field

March-2021

2D Vision Measuring Systems Market Size, Share & Trends Analysis Report By Application ( Commercial

March-2021

360 Degree Feedback Software Market Size, Share & Trends Analysis Report By Application ( Corporatio

March-2021

3D and 4D Technology Market Size, Share & Trends Analysis Report By Application (Entertainment, Cons

March-2021

3D Animated Films Market Size, Share & Trends Analysis Report By Application ( Children, Adults, Oth

March-2021

3D CAD Design Software Market Size, Share & Trends Analysis Report By Application (Small Business, M

March-2021

3D CAD Software Market Size, Share & Trends Analysis Report By Application ( Manufacturing, Automo

March-2021

3D CAD Software Market Size, Share & Trends Analysis Report By Application (Manufacturing, Automotiv

March-2021