Machine Condition Monitoring Market Size, Share, Growth & Industry Analysis, By Type (Vibration Monitoring, Thermography, Oil Analysis, Ultrasound, Others) By Deployment (On-Premise, Cloud-Based, Hybrid) By Monitoring Process (Portable Monitoring, Online Monitoring) By End-User (Manufacturing, Oil & Gas, Energy & Power, Aerospace & Defense, Others), By Region (North America, Europe, Asia-Pacific, Latin America, Middle East & Africa), and Regional Analysis, 2024-2031

Machine Condition Monitoring Market: Global Share and Growth Trajectory

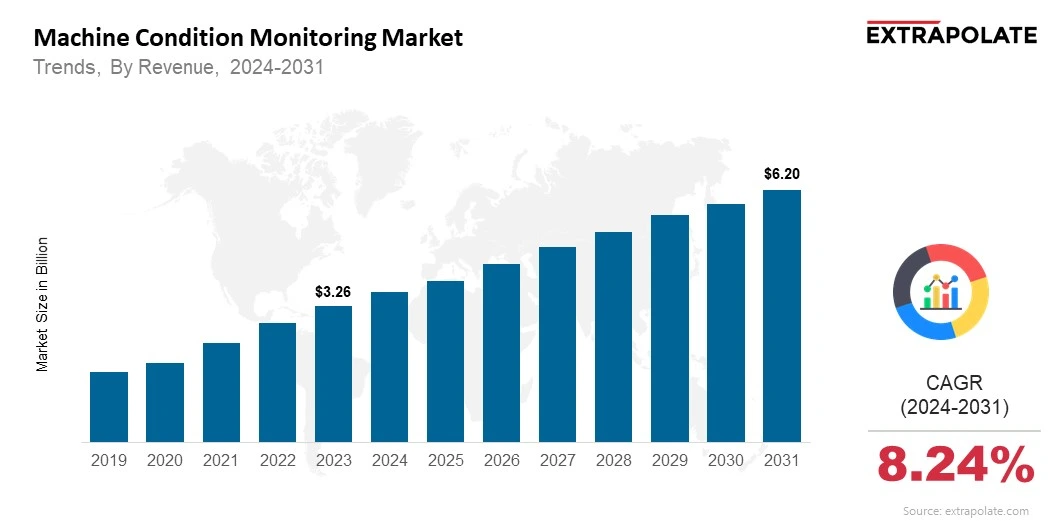

The global Machine Condition Monitoring Market size was valued at USD 3.26 billion in 2023 and is projected to grow from USD 3.56 billion in 2024 to USD 6.20 billion by 2031, exhibiting a CAGR of 8.24% during the forecast period.

The machine condition monitoring market is on fire as companies are looking for predictive maintenance and asset reliability across all industries. As companies prioritize operational efficiency and equipment longevity condition monitoring has become a must have.

These systems give you the visibility into machinery health so you can detect faults and failures before they become downtime or catastrophic damage. This market is being driven by the convergence of advanced sensor technologies, data analytics and industrial automation.

Industries such as manufacturing, oil and gas, energy, transportation and aerospace are rapidly adopting condition monitoring tools like vibration analysis, thermography, acoustic emission and oil analysis.

The growing adoption of machine learning and Industrial Internet of Things (IIoT) is further turning these systems into intelligent diagnostic platforms for real-time monitoring, remote access and predictive analytics.

As industries adopt smart maintenance and digital transformation the machine condition monitoring market is going to be big and sustained for the next few years.

Key Trends Driving Product Adoption

Key Trends Driving Product Adoption

Several key trends are driving product adoption:

Predictive Maintenance is the New Normal: Traditional maintenance models are being replaced by predictive maintenance. Companies are now preventing equipment failures by anticipating issues through real-time condition monitoring. This reduces downtime and extends asset life and saves operational costs.

IIoT Integration: Condition monitoring with IIoT platforms is changing how industries monitor equipment health. With connected sensors and cloud based analytics real-time data collection and analysis has become more accessible and efficient. This connectivity allows for centralised monitoring of machinery even across geographically dispersed locations.

Remote and Wireless Monitoring: With the proliferation of wireless technologies and remote access tools industries are deploying non-intrusive monitoring systems. These allow maintenance teams to monitor assets from afar, improving worker safety and streamlining data acquisition in hazardous or hard to reach areas.

Energy Efficiency: Monitoring systems are not only helping in detecting mechanical issues but also in optimising energy consumption. By analysing equipment performance these tools help in identifying energy inefficiencies and promoting sustainable industrial practices.

Adoption Across Multiple Industries: Condition monitoring is no longer limited to traditional heavy industries. Sectors like data centers, pharmaceuticals and renewable energy are adopting these systems to maintain uptime, quality and regulatory compliance.

Major Players and their Competitive Positioning

The machine condition monitoring market is characterized by strong competition and continuous innovation. Leading companies are focusing on developing smart, scalable, and integrated solutions to cater to the diverse needs of industrial applications. Key players include: General Electric (GE), Emerson Electric Co., SKF Group, Siemens AG, Honeywell International Inc., Schaeffler AG, National Instruments Corporation, Rockwell Automation, Inc., Parker Hannifin Corporation, ALS Limited, and Fluke Corporation (Fortive Corporation).

These companies are investing in R&D, forming strategic alliances, and expanding their product portfolios to strengthen market presence. Mergers, acquisitions, and collaborations with software and analytics firms are also common strategies aimed at providing end-to-end predictive maintenance solutions.

Consumer Behavior

End-users in the machine condition monitoring market are driven by cost-efficiency, ease of integration and ROI:

Proactive Maintenance Culture: Industrial companies are moving from reactive to proactive maintenance. As companies see the value in avoiding unscheduled downtime, they are investing in condition monitoring.

Customizable and Scalable Solutions: Companies want flexible systems that can be tailored to their machinery and scale with growth. Modular solutions that allow incremental upgrades rather than full overhauls are preferred.

Training and Usability: As monitoring technologies get more complex, end-users want systems that are user-friendly and require minimal training. Vendors that offer robust technical support, intuitive interfaces and integrated training modules have an edge.

Real-Time Data and Analytics: Access to real-time machine diagnostics and automated alerts is highly valued. Consumers want dashboards and mobile apps that provide on-demand insights and performance trends.

Pricing Trends

Pricing in the machine condition monitoring market varies by system complexity, monitoring technique and level of integration with asset management platforms. Vibration and basic thermography solutions are relatively affordable, while advanced systems with wireless, AI and cloud integration are more expensive.

Over time technology and economies of scale are reducing the cost barriers, especially for SMEs. Subscription models, pay-per-use and managed service contracts are emerging, making advanced condition monitoring more accessible. And the long term cost savings and equipment longevity make these systems a good investment.

Growth Drivers

Several key factors are driving the global machine condition monitoring market:

Industry 4.0: The Industry 4.0 wave is reshaping how companies manage their assets. Condition monitoring is a key component of digital factories and smart maintenance.

Growing Manufacturing: As global manufacturing output continues to rise, the need for asset reliability and maintenance strategies becomes more pressing. Condition monitoring is key to operational continuity.

Regulatory Compliance and Safety Standards: Strict regulations around machine safety and occupational hazards are forcing industries to adopt monitoring systems. These tools ensure compliance and worker safety by detecting faults early.

Awareness and Training: Awareness of predictive maintenance and the risks of unscheduled downtime is driving adoption in mid-market and emerging markets.

Sensing and Analytics: MEMS sensors, edge computing and AI analytics are making condition monitoring more effective, more widely adopted.

Regulatory Landscape

Machine condition monitoring is primarily governed by equipment safety, workplace regulations and environmental standards. These must align with:

- ISO 17359 – Guidelines for condition monitoring and diagnostics of machines.

- ISO 9001 & ISO 55000 – Quality management and asset management systems.

- OSHA Regulations – In the US, OSHA regulations require regular equipment inspection and maintenance.

Meeting these regulations ensures reliability, reduces liabilities and reputation.

Recent Developments

Several developments are changing the condition monitoring landscape:

- AI-Enabled Monitoring Systems: Top companies are embedding AI algorithms to allow systems to learn from historical data, predict failure modes and recommend maintenance schedules with high accuracy.

- Cloud-Based Monitoring Platforms: With cloud technology, monitoring systems now offer centralised data storage, visualisation and remote diagnostics, enabling better decision making and control.

- Portable and Wireless Solutions: New portable and wireless devices have made deployment easier and broader applications in remote and mobile machinery inspection.

- Strategic Collaborations: Big players are partnering with tech companies to integrate machine condition monitoring into broader industrial automation and digital twin ecosystems.

These are the signs of a shift towards intelligent, connected and efficient monitoring solutions for the smart industries.

Current and Future Growth Implications

Demand-Supply Analysis: Demand for condition monitoring is growing faster than supply in several regions. While global manufacturing and energy sectors are adopting advanced monitoring tools, supply chains are struggling to match this growing demand with cost effective and scalable solutions.

Gap Analysis: Despite growth, the market still has gaps in affordability, integration complexity and awareness – especially in small industries and emerging economies. Vendors are now focusing on providing compact, easy to deploy and cost effective solutions for underserved markets.

Top Companies in the Machine Condition Monitoring Market

- General Electric (GE)

- Emerson Electric Co.

- SKF Group

- Siemens AG

- Honeywell International Inc.

- Schaeffler AG

- National Instruments Corporation

- Rockwell Automation, Inc.

- Parker Hannifin Corporation

- ALS Limited

- Fluke Corporation (Fortive Corporation)

Machine Condition Monitoring Market: Report Snapshot

Segmentation | Details |

By Type | Vibration Monitoring, Thermography, Oil Analysis, Ultrasound, Others |

By Deployment | On-Premise, Cloud-Based, Hybrid |

By Monitoring Process | Portable Monitoring, Online Monitoring |

By End-User | Manufacturing, Oil & Gas, Energy & Power, Aerospace & Defense, Others |

By Region | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

Machine Condition Monitoring Market: Hot Segments

These segments will see high growth:

- Vibration Monitoring: Still dominant due to its ability to detect faults early across all rotating machinery.

- Online Monitoring: Demand for real-time, continuous equipment health data is driving online adoption especially in critical infrastructure industries like power generation and oil & gas.

- Cloud-Based Monitoring: Scalable and easy to access, cloud-based is gaining traction fast especially among SMEs.

New Developments

Recent developments driving growth:

- Edge Analytics: Real-time analytics at the device level means fault detection is immediate and data transmission is reduced.

- Integration with Digital Twins: Machine condition monitoring is now part of digital twin strategies, enabling virtual replication of physical assets for precise diagnostics and simulations.

- Multisensor Fusion: Systems now combine data from multiple sensors to give complete insight into machinery performance.

Machine Condition Monitoring Market: Growth Opportunities

Opportunities for further growth:

- Emerging Markets: Rapid industrialization in Asia-Pacific, Latin America and Africa means condition monitoring solutions for local operational needs.

- Customized Solutions for SMEs: As smaller firms adopt Industry 4.0 there is huge potential for affordable, plug-and-play monitoring tools for mid-tier companies.

- AI-Based Diagnostics: Enhanced diagnostic algorithms for predictive maintenance and automated decision-making can unlock efficiency across industries.

Extrapolate says:

The machine condition monitoring market is about to go into hyper growth. As industrial operations become more data driven, advanced diagnostics and predictive analytics is no longer optional – it’s mandatory. As manufacturers want uninterrupted productivity, smarter maintenance systems are the new must haves.

Fueled by sensor technology, AI and IIoT platforms this market has huge growth potential across industries. As companies want to minimize downtime, reduce costs and extend equipment life machine condition monitoring systems will be the new normal in industrial ecosystems.

ARE YOU SEEKING COMPREHENSIVE INSIGHT ON VARIOUS

MARKETS?

CONTACT OUR EXPERTS TODAY

Machine Condition Monitoring Market Size

- August-2025

- 140

- Global

- Machinery-Equipment

Related Research

0-Global Market Status and Trend Report 2015-2026

November-2020

2 Side Seal Machines-Global Market Status & Trend Report 2022-2030 Top 20 Countries Data

December-2020

3 Side Seal Machines-Global Market Status & Trend Report 2022-2030 Top 20 Countries Data

December-2020