Nanofiber Equipment Market Size, Share, Growth & Industry Analysis, By Equipment Type (Needle-Based Electrospinning, Needleless Electrospinning, Centrifugal Spinning, Force Spinning) By Scale (Lab-Scale, Pilot-Scale, Industrial-Scale) By Application (Healthcare, Filtration, Energy, Textile, Electronics, R&D) By End-User (Academic & Research Institutes, Industrial Manufacturers, Contract Research Organizations), and Regional Analysis, 2024-2031

Nanofiber Equipment Market: Global Share and Growth Trajectory

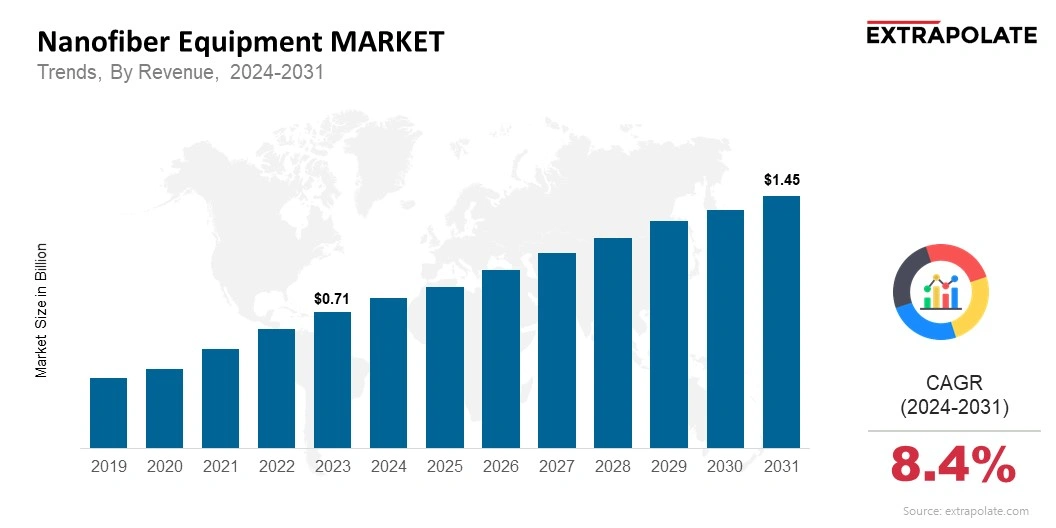

The global Nanofiber Equipment Market size was valued at USD 0.71 Billion in 2023 and is projected to grow from USD 0.82 Billion in 2024 to USD 1.45 Billion by 2031, exhibiting a CAGR of 8.4% during the forecast period.

The global market is witnessing steady growth, fueled by the expanding applications of nanofibers in sectors such as healthcare, filtration, energy, and electronics. Nanofiber equipment is essential for producing ultra-fine fibers with diameters typically below 100 nanometers, offering enhanced surface area, porosity, and mechanical strength. As demand for high-performance materials continues to rise, nanofiber production technologies are gaining significant attention from both industrial and academic communities.

Nanofiber equipment includes electrospinning machines, centrifugal spinning units, melt-blown systems, and other specialized apparatus designed to fabricate nanofibers with controlled morphology and uniformity. These machines are increasingly used in the development of advanced products such as tissue scaffolds, wound dressings, air and liquid filters, protective clothing, and battery separators. With the global shift toward lightweight, durable, and sustainable materials, nanofiber production has become a critical area of innovation.

One of the primary drivers of this market is the rising demand for nanofibers in medical and pharmaceutical applications. Nanofibers are highly effective in drug delivery systems, regenerative medicine, and biomedical implants due to their compatibility with biological systems. As healthcare systems worldwide invest in next-generation medical technologies, the need for reliable and scalable nanofiber production equipment is growing.

In addition, environmental concerns and air pollution control regulations are boosting the adoption of nanofiber-based filtration solutions. Nanofiber membranes offer superior particle retention and breathability, making them ideal for industrial filtration, face masks, and cleanroom applications. As a result, manufacturers are investing in automated, high-throughput nanofiber equipment to meet growing production demands efficiently.

Technological advancements are playing a crucial role in shaping the market. Innovations in multi-nozzle electrospinning, precision control systems, and hybrid production techniques are enabling faster production rates, reduced material waste, and enhanced fiber consistency. These developments are making nanofiber production more commercially viable and scalable across various end-use industries.

North America currently leads the nanofiber equipment industry, supported by strong R&D activities, advanced manufacturing infrastructure, and the presence of major equipment manufacturers. Europe also holds a significant share, while the Asia-Pacific region is emerging as a high-potential market due to increasing investments in nanotechnology research, expanding industrial applications, and favorable government initiatives.

Global industries are prioritizing performance, sustainability, and innovation. This will drive the demand for high-quality nanofiber production. The nanofiber equipment market is poised for long-term growth. Evolving applications and continuous technological progress will drive expansion across diverse industrial sectors.

The Nanofiber Equipment market is evolving rapidly as industries increasingly integrate nanotechnology into product development. Key trends include:

• Rising Use of Nanofibers in Medical Applications: Nanofibers are being adopted in wound dressings, drug delivery systems, and tissue engineering. This is prompting demand for precision equipment.

• High Growth in Air and Liquid Filtration: Nanofibers' filtration efficiency boosts industrial filter usage. This includes HVAC systems and water purification.

• Advancements in Electrospinning Technology: Needleless, multi-jet, and centrifugal spinning improve throughput. These innovations also boost scalability.

• Customization and Automation: Manufacturers seek flexible, automated equipment that supports diverse material formulations and mass production.

• R&D Expansion in Emerging Applications: Nanofiber integration in battery separators, sensors, and smart textiles is driving research-grade and pilot-scale equipment demand.

Major Players and their Competitive Positioning

The Nanofiber Equipment market includes both established manufacturers and niche technology developers focusing on innovation, speed, and cost-effectiveness. Companies such as Elmarco, SPINTECH, Inovenso, MECC Co., Ltd., and FNM Co., Ltd. lead the space with robust portfolios catering to industrial and academic applications. Competitive dynamics are shaped by equipment scalability, process control, fiber uniformity, and compatibility with different polymers.

Consumer Behavior Analysis

End-users in the Nanofiber Equipment market focus on:

• Scalability and Throughput: Choosing equipment based on batch vs. continuous production needs.

• Material Compatibility: Preference for machines that process a wide range of polymers and solvents.

• Precision and Repeatability: Ensuring consistent fiber diameters and structural properties.

• Ease of Operation: Demand for user-friendly interfaces and automated control systems.

• Research vs. Commercial Usage: Academia favors compact units. Industry prefers high-capacity, modular equipment.

Pricing Trends

Pricing in the Nanofiber Equipment market is largely determined by machine type (lab-scale, pilot-scale, industrial), degree of automation, and customization levels. Entry-level research equipment may range from USD 15,000 to USD 50,000, while fully automated industrial-scale systems can exceed USD 300,000. Prices also vary based on technical support, software features, and additional modules like humidity or temperature control.

Growth Factors

The market is experiencing robust growth driven by:

• Increased Demand for Nanofiber-Enabled Products: Especially in healthcare, filtration, and electronics.

• Government Funding for Nanotech Research: Supporting lab-scale equipment sales.

• Environmental and Energy Applications: Use of nanofibers in solar cells, batteries, and fuel cells boosting equipment demand.

• Collaborations Between Academia and Industry: Accelerating technology transfer and equipment adoption.

• Rising Focus on High-Performance Materials: Industries seeking ultra-lightweight, durable, and functional materials.

Regulatory Landscape

Direct regulations on nanofiber equipment are limited. Product safety standards for nanomaterials made with this equipment are evolving. Agencies like the EPA, FDA, and ECHA focus on nanomaterial risk assessment. They influence the operational parameters and safety features in nanofiber production equipment.

Recent Developments

The Nanofiber Equipment market is witnessing several advancements including:

• Needleless Electrospinning Systems: Enhancing safety and reducing maintenance.

• High-Throughput Industrial Units: Catering to mass production needs in filtration and textiles.

• Portable Lab-Scale Units: Supporting decentralized research in universities and startups.

• Real-Time Monitoring and AI Integration: Improving process control and predictive maintenance.

• Customizable Platforms: Modular equipment designs that support material experimentation.

Current and Potential Growth Implications

Demand-Supply Analysis

The demand for nanofiber equipment is high among academic institutions, contract manufacturers, R&D labs, and high-tech industries. Manufacturers are responding with standard and bespoke systems to cater to both pilot and full-scale operations.

Gap Analysis:

• High Capital Costs: Especially for industrial-scale machines.

• Limited Skilled Workforce: Operation and maintenance of nanofiber systems require technical expertise.

• Material Handling Complexities: Not all polymers are compatible with all spinning technologies.

• Lack of Standardization: Variations in fiber quality and process repeatability across equipment.

• Barriers to Commercial Scaling: Translating lab-scale success to mass production remains a hurdle.

Top Companies in the Nanofiber Equipment Market

• Elmarco

• Inovenso

• SPINTECH

• MECC Co., Ltd.

• FNM Co., Ltd.

• Electrospinz

• Nanospider (Contipro)

• Bioinicia

• Nanoflux

• Kato Tech Co., Ltd.

Report Snapshot

Segmentation | Details |

By Equipment Type | Needle-Based Electrospinning, Needleless Electrospinning, Centrifugal Spinning, Force Spinning |

By Scale | Lab-Scale, Pilot-Scale, Industrial-Scale |

By Application | Healthcare, Filtration, Energy, Textile, Electronics, R&D |

By End-User | Academic & Research Institutes, Industrial Manufacturers, Contract Research Organizations |

By Region | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

Nanofiber Equipment Market: High-Growth Segments

• Needleless and Multi-Nozzle Electrospinning: Reducing downtime and increasing throughput.

• Industrial-Scale Equipment: Supporting mass production of nanofiber-based filters and medical textiles.

• Asia-Pacific Market: Driven by government investment and manufacturing innovation.

• Energy Applications: Rising demand from battery, fuel cell, and solar tech developers.

• Customized R&D Platforms: Supporting startups and research institutions in nanotech exploration.

Major Innovations

• Automated Electrospinning Units: Reducing human error and enabling continuous production.

• Advanced Software Interfaces: Offering real-time control of voltage, flow rate, and environmental parameters.

• Hybrid Spinning Technologies: Combining electrospinning with centrifugal or melt spinning.

• Green Solvent Integration: Supporting sustainable nanofiber production.

• Multi-Material Capability: Enabling co-spinning and core-shell fiber production.

Nanofiber Equipment Market: Potential Growth Opportunities

• Development of Plug-and-Play R&D Systems: For educational and institutional markets.

• Strategic Collaborations: Between equipment manufacturers and material developers.

• Expansion into Smart Wearables and Defense: High-performance fibers for advanced textiles.

• Licensing of Proprietary Electrospinning Designs: Creating new revenue streams.

• Growth of Nanofiber-Enhanced Cosmetics and Food Packaging: Unlocking niche end-markets.

Extrapolate Research says:

The Nanofiber Equipment market is positioned at the forefront of nanotechnology-enabled innovation. As industries continue to push for stronger, lighter, and more functional materials, demand for scalable, efficient, and versatile nanofiber production systems will only intensify. With innovation accelerating and applications expanding, the market is entering a new phase of industrial maturity.

ARE YOU SEEKING COMPREHENSIVE INSIGHT ON VARIOUS

MARKETS?

CONTACT OUR EXPERTS TODAY

Nanofiber Equipment Market Size

- May-2025

- 140

- Global

- Information-Technology-Communication-IoT

Related Research

2018-2023 Commercial Interior Design Market Size, Share & Trends Analysis Report By Application ( O

March-2021

2018-2023 Industrial Product Design Market Size, Share & Trends Analysis Report By Application ( Tr

March-2021

2D Animation Software Market Size, Share & Trends Analysis Report By Application (Construction Field

March-2021

2D Vision Measuring Systems Market Size, Share & Trends Analysis Report By Application ( Commercial

March-2021

360 Degree Feedback Software Market Size, Share & Trends Analysis Report By Application ( Corporatio

March-2021

3D and 4D Technology Market Size, Share & Trends Analysis Report By Application (Entertainment, Cons

March-2021

3D Animated Films Market Size, Share & Trends Analysis Report By Application ( Children, Adults, Oth

March-2021

3D CAD Design Software Market Size, Share & Trends Analysis Report By Application (Small Business, M

March-2021

3D CAD Software Market Size, Share & Trends Analysis Report By Application ( Manufacturing, Automo

March-2021

3D CAD Software Market Size, Share & Trends Analysis Report By Application (Manufacturing, Automotiv

March-2021