Polycarbonate Market Size, Share, Growth & Industry Analysis, By Product Type (Sheets, Films, Fibers, Compounds, Blends) By Application (Automotive, Electronics, Construction, Optical Media, Medical Devices, Packaging) By End-User (OEMs, Industrial Manufacturers, Construction Firms, Electronics & Consumer Goods Companies), and Regional Analysis, 2024-2031

Polycarbonate Market: Global Share and Growth Trajectory

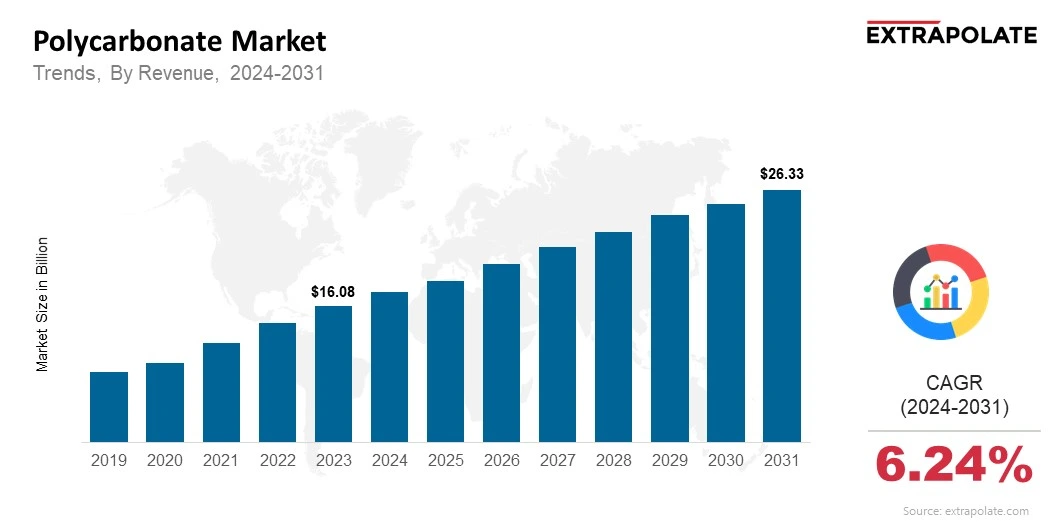

The global Polycarbonate Market size was valued at USD 16.08 Billion in 2023 and is projected to grow from USD 17.23 Billion in 2024 to USD 26.33 Billion by 2031, exhibiting a CAGR of 6.24% during the forecast period.

The global polycarbonate market is growing quickly. This growth is driven by its wide use across many industries. Polycarbonate is a high-performance thermoplastic. It is known for its strength, clarity, heat resistance, and impact resistance.

These features make it ideal for industries like automotive, electronics, construction, optical media, and medical devices. Demand is rising as manufacturers look for materials that are both lightweight and durable. Polycarbonate is used in many products. These include safety goggles, CDs, headlamps, roofing sheets, and electronic parts.

New bio-based and recyclable polycarbonates are supporting sustainability goals. This has further boosted market growth. With ongoing innovations in production and growing demand for reliable, eco-friendly materials, the polycarbonate market is entering a new phase of expansion.

Key Market Trends Driving Product Adoption

Key Market Trends Driving Product Adoption

Growing Electronics and Automotive Demand

Polycarbonate is widely used in the automotive industry for roof systems, instrument panels, and headlamp lenses. Automobile manufacturers are substituting lightweight materials like polycarbonate for metal and glass components in an effort to increase fuel efficiency. Because of its durability and insulating qualities, the polymer is utilized in electronics for housing, connectors, and display screens.

Transitioning to Recyclable and Sustainable Materials

The sector is moving toward more sustainable solutions as environmental concerns grow. Prominent businesses are creating recyclable and bio-based polycarbonate resins to lessen their reliance on fossil fuels and their negative effects on the environment. In line with the general market trend, these green initiatives are gaining traction across end-use categories, such as consumer items and automobiles.

Infrastructure Development and Urbanization

Rapid urbanization and global infrastructure development has created a huge demand for robust construction materials. Polycarbonate sheets being light weight and impact resistant are being used in roofing, glazing and skylight applications. Their UV resistance and transparency makes them a suitable choice for public and commercial architecture, driving the market growth.

Manufacturing Process Technologies

Polycarbonate now has new uses thanks to advancements in 3D printing, extrusion, and injection molding. Complex shapes and very precise products with little material waste are now possible because to these developments. Improvements to the compounding process have also improved the flame retardancy, UV resistance, and optical clarity of polycarbonate grades for use in lighting and aerospace.

Major Players and their Competitive Positioning

The polycarbonate market is competitive and consolidated with major global players leading the innovation. Some of the key players are:- Covestro AG, SABIC, Mitsubishi Engineering-Plastics Corporation, Teijin Limited, Chi Mei Corporation, LG Chem Ltd., Trinseo S.A., Formosa Chemicals & Fibre Corp., Idemitsu Kosan Co., Ltd., Lotte Chemical Corporation.

They are expanding capacity, integrating vertically and launching sustainable product lines to strengthen their presence. Strategic partnerships, R&D investments and new bio-based polycarbonate developments are key to their business models.

Consumer Behavior Analysis

Lightweight and Durable Products

Consumers are opting for products that are both lightweight and durable. In automotive, construction and electronics, polycarbonate means strength and efficiency. This is driving demand for polycarbonate solutions across developed and emerging markets.

Environmental Awareness and Green Choices

End users are becoming more environmentally aware. This means demands for recyclable and renewable resource polycarbonate products. Individual consumers and corporate buyers are aligning their purchasing decisions with their values and driving growth for green polycarbonates.

High-Performance Materials in Daily Products

As consumer expectations for durability and product life increase, manufacturers are turning to polycarbonate for a wide range of consumer goods – from luggage and bottles to eyewear and electronics. The trend for high-performance, beautiful products is driving polycarbonate into daily use items.

Government Standards and Certifications

Tighter regulations on safety and emissions are pushing consumers and manufacturers towards compliant materials. Polycarbonate’s flame retardancy, FDA and RoHS compliance and high performance under stress make it the material of choice in regulated industries like medical devices and electrical appliances.

Pricing Trends

Pricing of polycarbonate is influenced by several factors including raw material costs (bisphenol A), global supply demand dynamics and energy costs of production. Crude oil prices and feedstock availability also impact price fluctuations.

In recent years supply chain constraints, geopolitical instability and energy price volatility have put pressure on pricing. However, production technology advancements and scaling up of capacities in Asia-Pacific especially in China and India is helping to stabilize prices to some extent. The market has also seen increased competition which is putting downward pressure on pricing in commoditized segments. Premium applications especially in medical and aerospace are still commanding higher margins.

Growth Factors

Wider Applications Across Multiple Industries

Polycarbonate is versatile. It’s used in automotive, electronics, aerospace, packaging, healthcare, agriculture and optical storage industries. This broad usage helps the market to be stable even if one segment slows down. It supports global growth.

Rising Demand for Electric Vehicles (EVs)

Governments and automakers are promoting EVs. Polycarbonate is gaining popularity as a lightweight material that improves energy efficiency. It’s now being used in EV battery casings, interior parts and lighting systems.

Innovations in Recycling and Circular Economy

Polycarbonate is recyclable. It’s perfect for circular economy models. With more awareness and new regulations, companies are investing in better recycling technologies. Closed-loop systems and take-back programs are helping to reduce waste and reuse materials.

Smart Cities and Green Buildings

Smart city projects and green buildings are driving demand for advanced materials. Polycarbonate is used in transparent walls, noise barriers, solar panels and skylights. Its strength, light weight and clarity makes it a material of the future.

Regulatory Landscape

The polycarbonate industry is regulated by environmental, health and safety regulations that affect production, usage and disposal. Key regulations are:

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe for chemical manufacturing.

- FDA Approvals for food-contact and medical-grade polycarbonate products.

- RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) for polycarbonate in electronics.

- ISO 9001 and ISO 14001 Certifications for quality management and environmental impact reduction.

Tight regulations are driving innovation in low-toxicity and BPA-free polycarbonate for food, baby products and medical devices.

Recent Developments

- Bio-based Polycarbonate Launches:

Covestro has developed resins from renewable sources. They meet sustainability and performance. Mitsubishi Chemical Group introduced new grades of BENEBiOL biomass-based polycarbonate diol in June 2025. These grades have more than 80% sustainable content and are intended for use in polyurethanes for furniture finishes, synthetic leather, and automotive coatings. - Strategic Expansions:

SABIC and Trinseo are expanding in Asia-Pacific and Europe to meet growing demand. - Collaborations with Tech Giants:

Polycarbonate makers are working with electronics companies. Together they are creating thinner and stronger casings for devices. - Additive Manufacturing Innovations:

Polycarbonate is growing in 3D printing. It’s ideal for industrial and aerospace parts due to its strength and heat resistance.

Current and Potential Growth Implications

Demand-Supply Analysis

Global polycarbonate demand is up. Automotive, electronics and construction are the key drivers. But raw material price fluctuations and regional production capacity constraints are affecting supply. Asia-Pacific is the biggest user and producer. China is the top player in the region.

Gap Analysis

Although polycarbonate is widely used, high production cost is a challenge. Its dependence on petrochemical feedstock makes it less attractive in price sensitive markets.

Acrylic and ABS are cheaper in some areas. There’s also a gap in scaling up bio-based polycarbonate. They need to match the strength and quality of traditional ones.

Top Companies in the Polycarbonate Market

- Covestro AG

- SABIC

- Mitsubishi Engineering-Plastics Corporation

- Teijin Limited

- Chi Mei Corporation

- LG Chem Ltd.

- Trinseo S.A.

- Formosa Chemicals & Fibre Corp.

- Idemitsu Kosan Co., Ltd.

- Lotte Chemical Corporation

Polycarbonate Market: Report Snapshot

Segmentation | Details |

By Product Type | Sheets, Films, Fibers, Compounds, Blends |

By Application | Automotive, Electronics, Construction, Optical Media, Medical Devices, Packaging |

By End-User | OEMs, Industrial Manufacturers, Construction Firms, Electronics & Consumer Goods Companies |

By Region | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

Polycarbonate Market: High-Growth Segments

- Automotive:

Polycarbonate is widely used in electric vehicle parts. It helps reduce weight and improve performance. - Construction:

Fast urban growth in developing countries is raising demand. Polycarbonate panels are used for buildings and safety needs. - Electronics:

More consumer electronics means more need for strong, heat-resistant materials like polycarbonate. - Medical Devices:

BPA-free polycarbonate is growing in use. It’s used in medical housings and surgical tools.

Major Innovations

- BPA-Free Polycarbonate:

New methods are removing bisphenol A. This helps meet health and safety rules. - Nano-Reinforced Polycarbonate:

Adding nanomaterials makes it stronger and more heat-resistant. It’s ideal for aerospace and defense uses. - Smart Polycarbonate Films:

These films are clear and conductive. They’re used in touch screens and flexible electronics.

Polycarbonate Market: Potential Growth Opportunities

- Emerging Markets:

Fast industrial growth in Latin America and Southeast Asia is creating new demand for polycarbonate. - Eco-Friendly Production:

New green chemistry methods may cut production costs. This can help polycarbonate reach more markets. - Hybrid Blends:

Mixing polycarbonate with other plastics like ABS and PET creates custom materials for specific uses. - Digital Manufacturing:

Polycarbonate is being used more in 3D printing. This opens new markets in aerospace, cars, and product design.

Extrapolate says:

Over the course of the projected period, the polycarbonate market is expected to rise significantly. Sustainable, long-lasting, and lightweight materials are becoming more and more popular in industries. One particularly good option is polycarbonate. It is utilized in medical devices, electronics, construction, and automobiles. Its adaptability satisfies demand in numerous industries.

Variants of bio-based polycarbonate are gaining popularity. Additionally, improved manufacturing methods are improving the quality of products. More innovation is being driven by stringent safety and environmental regulations. Businesses will benefit from investing in circular economy concepts. The secret to long-term success will be sustainable production. Polycarbonate is prepared to lead as the market for more environmentally friendly and intelligent materials expands. It will be a key component of industrial solutions of the future.

ARE YOU SEEKING COMPREHENSIVE INSIGHT ON VARIOUS

MARKETS?

CONTACT OUR EXPERTS TODAY

Polycarbonate Market Size

- July-2025

- 148

- Global

- Chemicals-and-Advanced-Materials

Related Research

Carbohydrases Market Size, Share & Trends Analysis Report By Application (Food and beverages, Anima

January-2021

1,2,3,4-Tetrahydroquinaldine Reagent (CAS 1780-19-4) -Global Market Status & Trend Report 2022-2030

August-2021

1,2,3,4-Tetrahydroquinaldine Reagent (CAS 1780-19-4) -Global Market Status and Trend Report 2022-203

August-2021

1,2,3,4-Tetrahydroquinoline Reagent (CAS 635-46-1)-Global Market Status & Trend Report 2022-2030 Top

August-2021

1,2,3,4-Tetrahydroquinoline Reagent (CAS 635-46-1)-Global Market Status and Trend Report 2022-2030

August-2021