Ceramics Additive Market Size, Share, Growth & Industry Analysis, By Material Type (Ceramic Powders, Ceramic Inks) By Technology (Stereolithography (SLA), Selective Laser Sintering (SLS), Inkjet Printing, Fused Deposition Modeling (FDM)) By Application (Aerospace, Automotive, Healthcare, Electronics, Industrial Applications, Others), and Regional Analysis, 2024-2031

Ceramics Additive Market: Global Share and Growth Trajectory

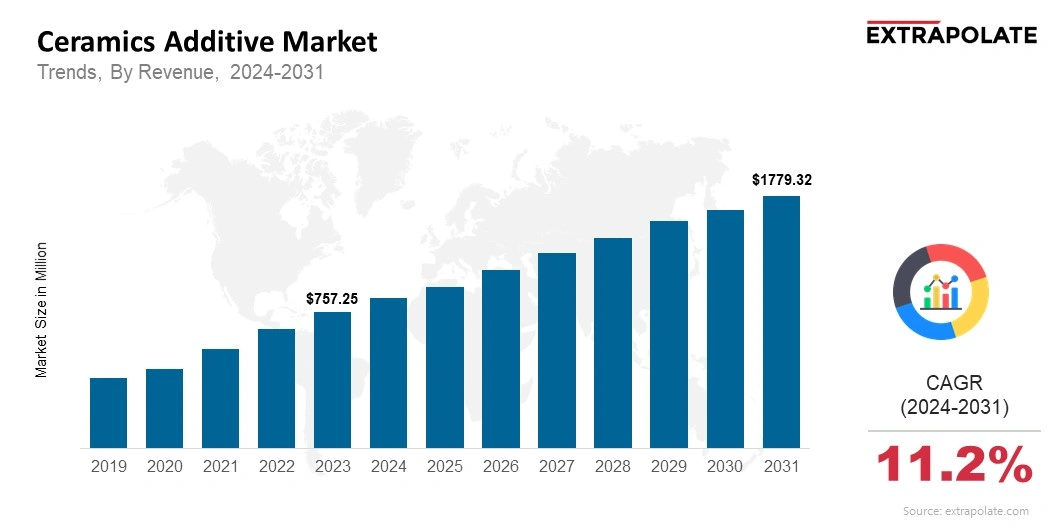

The global Ceramics Additive Market size was valued at USD 757.25 Million in 2023 and is projected to grow from USD 848.79 Million in 2024 to USD 1779.32 Million by 2031, exhibiting a CAGR of 11.2% during the forecast period.

The global market is experiencing explosive growth, driven by technological advancements in additive manufacturing, increasing demand for complex and customized ceramic parts, and growing applications across various industries such as aerospace, automotive, healthcare, and electronics. This market includes the use of 3D printing technologies to create high-performance ceramic components, offering unique advantages such as design flexibility, reduced material waste, and shorter production cycles. As industries continue to embrace these innovations, ceramics additive manufacturing is gaining traction due to its ability to produce intricate, lightweight, and highly durable ceramic parts that traditional methods cannot achieve.

As the technology evolves, ceramics additive solutions are increasingly being used to meet the need for high-precision, customized, and cost-effective components. These advanced manufacturing techniques provide manufacturers with enhanced control over production, enabling the creation of complex geometries with improved material properties such as thermal stability, corrosion resistance, and mechanical strength. Furthermore, as sustainability becomes a growing concern, ceramics additive manufacturing offers a more environmentally friendly approach by minimizing material waste and optimizing energy consumption compared to conventional manufacturing methods.

The market is expanding due to rising demand for advanced ceramics in aerospace, where lightweight, heat-resistant materials are essential. The automotive and healthcare industries are also adopting this technology for specialized parts like turbine blades, medical implants, and electronic components. This growing interest will continue driving innovation in materials and processes, accelerating market growth.

In conclusion, the market is poised for growth. Technological advancements, demand for customized solutions, and the rise of additive manufacturing are driving this trend. The evolution of 3D printing technologies and materials will create new opportunities, further expanding the market.

The ceramics additive market is marked by fast tech advancements and rising demand for custom solutions. There is also a push for more sustainable production methods. Key trends driving market growth include:

- High-Performance Materials: Ceramics are becoming the go-to material for components with enhanced properties. This is especially true in aerospace and automotive industries.

- Customized Solutions: Additive manufacturing enables complex geometries and custom ceramic parts. These are hard to achieve with traditional methods.

- Sustainability: Ceramics in additive manufacturing are seen as more sustainable. They reduce waste and are more efficient than traditional production methods.

- Integration with Digital Manufacturing: Additive manufacturing and digital technologies work together for precise design control. This improves quality control and reduces lead times.

- Healthcare Applications: Ceramics are gaining traction in healthcare. 3D-printed implants and prosthetics are valued for their biocompatibility and durability.

Major Players and their Competitive Positioning

The ceramics additive market is led by key players like 3D Systems, Stratasys, Materialise, and XJet Ltd. These companies are innovating to maintain their edge by developing new materials and improving additive manufacturing. Smaller players and startups are contributing with specialized ceramic powders and new printing techniques

Consumer Behavior Analysis

Consumers across various industries are adopting ceramics additive manufacturing for the following reasons:

- High-Performance Needs: The demand for advanced, durable materials is growing in aerospace and automotive. This is driving ceramics adoption in additive manufacturing.

- Cost-Effectiveness: Ceramics additive manufacturing eliminates the need for costly molds and tooling. This makes it an attractive option for many industries.

- Customization: Manufacturers are seeking custom-designed ceramic components. Additive manufacturing delivers these with better precision and efficiency.

- Material Efficiency: Additive manufacturing uses materials efficiently. It reduces waste and promotes more sustainable manufacturing.

Pricing Trends

Pricing in the ceramics additive market depends on material type, technology, and production scale. These factors affect costs. High-performance ceramics have premium prices. This is especially true for specialized applications like aerospace and healthcare. As technologies mature and adoption grows, the cost of ceramics additive manufacturing will decrease. This will make it more accessible to more industries.

The market is growing steadily. There have been significant advancements in material science and manufacturing technologies. The market will grow in North America, Europe, and Asia-Pacific. Strong demand, better manufacturing, and wider applications are driving this.

Growth Factors

Several factors are driving the growth of the ceramics additive market:

- Technological Advancements: Advances in 3D printing, like precision printing, are expanding ceramic use. Multi-material capabilities are also driving growth in additive manufacturing.

- Demand for Customization: Industries want custom, complex ceramic parts. Traditional methods can't easily produce these.

- Cost and Waste Efficiency: Additive manufacturing is more sustainable. It reduces material waste and cuts out the need for costly molds.

- Rising Demand in Healthcare: Demand for custom ceramic implants is rising. This boosts ceramics additive manufacturing in healthcare.

Regulatory Landscape

The regulatory landscape for ceramics additive manufacturing is changing. This is especially important in healthcare, where safety and biocompatibility are crucial. Compliance with regulatory standards is crucial. This is particularly for medical devices and implants in the market.

Recent Developments

The ceramics additive market is continually advancing with the introduction of new materials, technologies, and applications. Some of the latest developments include:

- New Ceramic Materials: Innovations in ceramic powders are improving performance. They also increase the versatility of ceramics in additive manufacturing.

- Improved Printing Techniques: Progress in 3D printing makes ceramic parts with finer detail plus better build quality. This permits intricate shapes.

- Healthcare and Medical Applications: Ceramic use increases in three-dimensional printed medical tools and implants. This is because they work well with living tissue and offer structural stability.

- Sustainability Innovations: New methods aim to cut material waste and energy use. These approaches are gaining attention in additive manufacturing.

Current and Potential Growth Implications

- Demand Supply Analysis

Demand for ceramics in additive manufacturing is growing. This is driven by industrial, automotive, healthcare, and electronics applications. Demand for ceramics in additive manufacturing is rising. Industrial, automotive, healthcare, and electronics applications are driving this growth.

- Gap Analysis

The ceramics additive market shows strong potential. However, there are areas that need improvement:

- Material Availability: The supply of specialized ceramic materials is limited. This could hinder growth.

- Process Optimization: Additional gains to print speed plus material reliability are needed for general acceptance. Widespread implementation depends on these gains.

- Cost Reduction: The high cost of some ceramic materials and 3D printing tech limits adoption. This is especially true in cost-sensitive industries.

Top Companies in the Ceramics Additive Market

- 3D Systems

- Stratasys

- Materialise

- XJet Ltd.

- ExOne

- EOS GmbH

- Sinterit

- Lithoz GmbH

Report Snapshot

Segmentation | Details |

By Material Type | Ceramic Powders, Ceramic Inks |

By Technology | Stereolithography (SLA), Selective Laser Sintering (SLS), Inkjet Printing, Fused Deposition Modeling (FDM) |

By Application | Aerospace, Automotive, Healthcare, Electronics, Industrial Applications, Others |

By Region | North America, Europe, Asia-Pacific, Middle East & Africa, South America |

High Growth Segments

The following market segments are expected to experience significant growth:

- Aerospace: Ceramics are used more in aerospace. Their thermal resistance and strength make them perfect for high-performance parts

- Healthcare: The demand for 3D-printed ceramic implants and prosthetics is rising. Their biocompatibility and mechanical properties drive this growth.

- Automotive: Ceramics are now used in automotive parts. They improve performance and durability.

Major Innovations

Innovation is key to staying competitive in the ceramics additive market. Some of the latest innovations include:

- Advanced Ceramic Materials: New ceramic powders are improving the strength and functionality of printed parts. These innovations enhance performance.

- Hybrid Manufacturing: Combining additive manufacturing with traditional methods boosts capabilities. This enhances overall production.

- Increased Automation: Automated printing processes are cutting production time. They are also boosting efficiency.

Potential Growth Opportunities

Companies in the ceramics additive market face several challenges:

- Intense Competition: There is rising competition from established players and new startups.

- Material and Technology Advancements: There is a need for ongoing research into new ceramic materials. Advancements in printing technologies are also essential.

- Cost and Scalability: Reducing material costs is key. Improving technology scalability for mass production is also crucial.

Extrapolate Research says:

The global ceramics additive market is set for strong growth. Industries are increasingly adopting new manufacturing technologies. Companies that capitalize on advancements in materials, technology, and customization will be well-positioned. They will lead in this dynamic market.

ARE YOU SEEKING COMPREHENSIVE INSIGHT ON VARIOUS

MARKETS?

CONTACT OUR EXPERTS TODAY

Ceramics Additive Market Size

- April-2025

- 140

- Global

- Chemicals-and-Advanced-Materials

Related Research

Carbohydrases Market Size, Share & Trends Analysis Report By Application (Food and beverages, Anima

January-2021

1,2,3,4-Tetrahydroquinaldine Reagent (CAS 1780-19-4) -Global Market Status & Trend Report 2022-2030

August-2021

1,2,3,4-Tetrahydroquinaldine Reagent (CAS 1780-19-4) -Global Market Status and Trend Report 2022-203

August-2021

1,2,3,4-Tetrahydroquinoline Reagent (CAS 635-46-1)-Global Market Status & Trend Report 2022-2030 Top

August-2021

1,2,3,4-Tetrahydroquinoline Reagent (CAS 635-46-1)-Global Market Status and Trend Report 2022-2030

August-2021